Thoughts on Kite Repair — by Tim Elverston

WindFire Designs

So, I’ve been repairing kites for a long time

now. When I first started it was like learning to

sew all over again. I'd then been sewing for over 10

years and thought I was already pretty damn good at

it. Many of the challenges it presented were

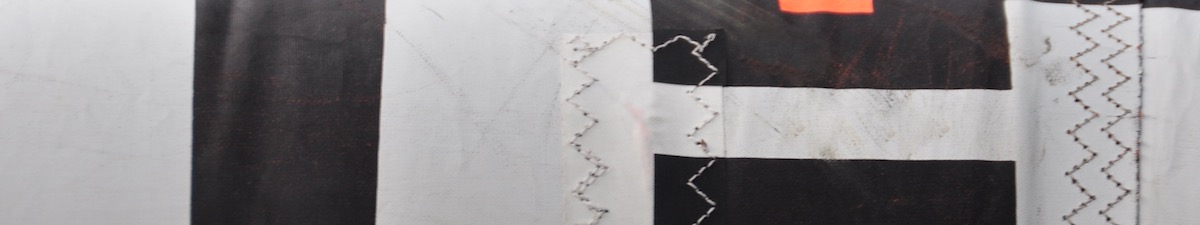

expected. Stiff fabric in tight places and sewing

panels long after the kite is complete that were

added near the beginning of the manufacturing

sequence. All these things were difficult to get not

only right but also looking sharp. One thing in

particular though has been a real plateau to get to

for me. Sometimes there is a situation that happens

where a seam's thread will fail all the way down.

Like a zipper had been opened. The kitesurfing kites

have inflatable struts that run down the sail and

sometimes they come away from the sail in this way.

Okay so back to sewing 201. On long seams you have

to manage the creep of the lower layer. Keep it from

bunching up. Well here is the thing. You are not

working on your own kite. You are working on a kite

built in China on a seam that was previously already

sewn. Your're trying to emulate the way it was sewn

to begin with, matching the other struts and

especially the strut you are sewing on. If you sew

it perfectly, it isn't perfect. Keeping the layers

from moving isn’t the objective anymore. You

have to allow the lower layer to creep the exact

amount that the Chinese operator and their machine

did. Otherwise you will end up with a cm or more of

empty stitch holes on the bottom.

What is really interesting for me about this is the

mental state it puts me into. I like to imagine that

I have been at my machine all day long and didn't

get coffee and I am not making any money and I will

go home to 12 people in my 400 square foot

apartment. I like to think of the floor director

looking over my shoulder and not saying anything but

writing something down on a clipboard and moving

along to the next machine. Then I think of the

person I’m repairing the kite for. How he or

she will be thinking about how much their next kite

will cost, the fact that they are so expensive.

Like nearly all of us in this disposable world, never putting the two simple facts together that they are paying me $80.00 and shipping both ways to sew a simple 6 foot repair, meanwhile telling me how wonderfully reasonable my prices are — which is certainly true. However, the entire kite, bag, and 4-color printing on both the kite's fabric, and in the included instructions, was priced at retail of say $949.99 and was shipped across an ocean of water in a container on a ship. How does this happen? The kite cost the retail storeowner a little over half that. That means the distributor bought it from the factory for close to 1/4 of the retail cost. So the factory gets $200 for this kite. Out of that comes material and overhead. Where do the wages for the workers fit in? It’s just amazing.

I see in these kites a precision of manufacturing that sometimes makes me doubt my own abilities. I find little Chinese characters hidden under the seams to indicate where each of the hundred and fifty or so panels and pieces go. I see an eyelash stuck under the adhesive of a reinforcement strip. The people who made this kite probably know little of how it is used and certainly will never be able to afford one. What do they dream? Could they ever imagine that I would be sewing on seams that they made? Do they think of the kite in the sky? I can only sew and wonder.

stitching and thinking

WindFire Designs

Kite repair service in a few easy steps

How to have your kites serviced

by WindFire Designs:

1: Print or fake our WindFire Designs Repair Ticket

2: Allow the kite to dry and shake off loose sand

3: View our checklist

4: Pack the kite in a smallish box

5: Ship to WindFire Designs